Series PL

Description:

The Series PL™ close coupled booster pumps are specifically designed for quiet operation in hydronic, radiant and geothermal heating and cooling systems. These inline permanently lubricated pumps are available in cast iron or lead-free† bronze body construction.

Operating Data:

Maximum working pressure . . . . . . . . . . .150 psi (10 bar)

Maximum operating temperature . . . . . . . .225°F (107°C)

Materials of Construction:

Pump Body . . . . . . . . . . . . . Cast Iron or Lead-Free† Bronze

Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel

Impeller . . . . . . . . . . . . . . . . . . . . . . .30% Glass Filled Noryl®

PL-55 & PL-130. . . Glass Filled PPS

Shaft . . . . . . . . . . . . . . . . . . . .Solid High-Strength Alloy Steel

Seal System . . . . . . . . . . . . . . . . . . . Carbon/Silicon Carbide

Bearings . . . . . . . . XL11™Permanently Lubricated Sealed

Precision Bearings

Motor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ODP

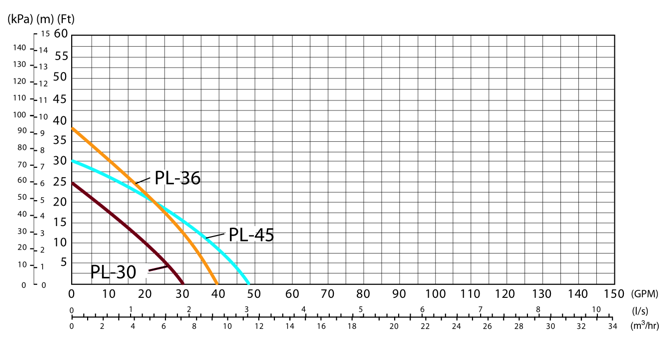

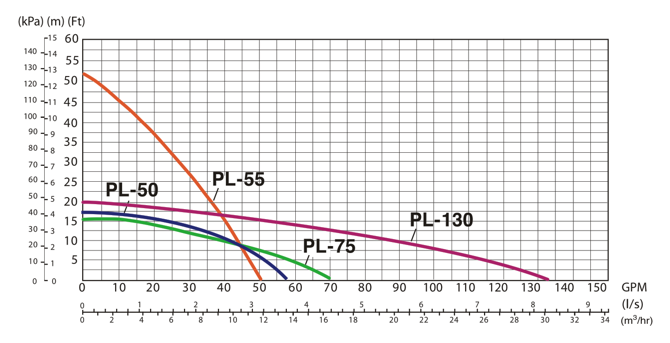

Curves:

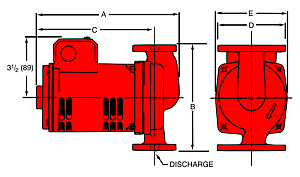

Dimensions and Weights:

| Cast Iron | Lead-Free† Bronze | Flange Size Inches - NPT | Motor Characteristics* | Dimensions in inches (mm) @ 60 Hz (Open Drip-Proof) |

Approx. Shipg. Wt. Ibs. (Kg) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model No. | Part No. | Model No. | Part No. | HP | ø | Voltage | RPM | A | B | C | D | E | ||

| PL-30 | 1BL012 | PL-30B | 1BL013LF | 3⁄4 | 1⁄6 |

1 | 115 | 2650 | 8 5⁄8 (219) | 6 3⁄8 (162) | 7 1⁄8 (181) | 4 3⁄16 (106) | 4 3⁄8 (111) | 11.6 (5.3) |

| 1 & 1 1⁄4 | ||||||||||||||

| 1 1⁄2 | ||||||||||||||

| PL-36 | 1BL001 | PL-36B | 1BL003LF | 3⁄4 | 1⁄6 | 3300 | 8 5⁄8 (219) | 6 3⁄8 (162) | 7 1⁄8 (181) | 4 3⁄16 (106) | 4 3⁄8 (111) | 13.1 (6.0) | ||

| 1 & 1 1⁄4 | ||||||||||||||

| 1 1⁄2 | ||||||||||||||

| PL-45 | 1BL002 | PL-45B | 1BL004LF | 1 | 1⁄6 | 3300 | 9 1⁄8 (232) | 8 1⁄2 (216) | 7 1⁄4 (184) | 4 5⁄8 (117) | 4 3⁄8 (111) | 14.5 (6.6) | ||

| 1 1⁄4 & 1 1⁄2 | ||||||||||||||

| PL-50 | 1BL016 | PL-50B | 1BL017LF | 1 |

1⁄6 | 3300 | 9 1⁄8 (232) | 8 1⁄2 (216) | 7 1⁄4 (184) | 4 5⁄8 (117) | 4 3⁄8 (111) | 14.5 (6.6) | ||

| 1 1⁄4 & 1 1⁄2 | ||||||||||||||

| PL-55 | 1BL032 | PL-55B |

|

3⁄4 | 2⁄5 | 3250 | 9 9⁄16 (243) | 6 3⁄8 (162) | 7 5⁄16 (202) | 4 3⁄16 (106) | 4 3⁄4 (121) | 13.1 (6.0) | ||

| 1 & 1 1⁄4 | ||||||||||||||

| 1 1⁄2 | ||||||||||||||

| PL-75 | 1BL034 | PL-75B | 1BL035LF | 2 | 1⁄6 | 3400 | 9 15⁄16 (252) | 8 1⁄2 (216) | 7 3⁄8 (187) | 5 3⁄16 (132) | 4 5⁄8 (117) | 18.5 (8.4) | ||

| PL-130 | 1BL063 | PL-130B | 1BL065LF | 2 | 2⁄5 | 3200 | 10 3⁄4 (273) | 8 1⁄2 (216) | 8 1⁄4 (210) | 5 3⁄16 (132) | 5 1⁄8 (130) | 22 (10) | ||

* 230/60/1 motors available upon request. Models PL-75 and PL-130 have a four bolt hole flange connection, all others have two bolt hole flange connectors.

Dimensions are approximate and subject to changes. Contact factory for certified dimensions.

† Contains less than 0.25% lead content by weight on wetted surfaces.